Source - Dmytro Novitskyi

The development of digital technologies significantly influences all spheres of our life. Thanks to them, we have entered the era of the Fourth Industrial Revolution that means a new approach to the organization of work, leisure, and lives of people. Its emergence is connected with the mass distribution of the Internet. The worldwide web has had a major impact on the development of society and has become a prerequisite for creating the modern concept that is called “Industry 4.0 in production”. The concept is based on the transition to automated manufacturing managed by intellectual systems (artificial intelligence) in real-time. In other words, the Fourth Industrial Revolution means the full automation of production processes, which will increase the performance of companies, improve the safety of the staff, and allow companies to create completely new products.

Background

Over the long course of human history, mankind has survived three industrial revolutions that had their peculiar features and results:

- The first one started at the end of the 18th century and is called “The Great Industrial Revolution”. Replacing manual labor with mechanization and agrarian upheaval, which released a much cheap labor force, were prerequisites to this revolution. In the period up to the beginning of the 19th century, there were many new inventions, including the invention of the power looms and spinning frames, steam and water engines, agricultural machines. The first revolution led to the establishment of the capitalistic order and accelerated the relocation of people to big cities.

- The second revolution happened in the second half of the 19th and the beginning of the 20th century. Thanks to the achievements in chemistry and physics, people were able to implement into production many scientific discoveries, including such key achievements as electrification, the invention of the telegraph and the phone, the usage of containers in mass production.

- The third revolution evolved in the 1960s. Its specific characteristics are digitization, software-based production, and the application of information and communication technologies in the industry. Some meaningful for people things, such as the computer and the mobile phone, was invented in that period.

Directions in Industry 4.0

Modern Industry 4.0 manufacturing is a growing tandem of technological and industrial innovations. The new concept includes many directions which will result in revolutionary changes both in industry and society in general.

Internet of Things and Industrial Internet of Things

The Internet of Things (IoT) is a concept of data transfer between physical objects. Data exchange can be carried out between sensors, machines, and other devices that can solve tasks without human intervention. In some cases, people can participate in processes, for example, during the implementation of the “smart home” system.

The Industrial Internet of Things (IIoT) is a type of IoT that implies data exchange between the factory or plant equipment. The assets are equipped with controllers and sensors that direct information to the corresponding services of the company. The result of the IIoT platform implementation is the establishment of automated production and increasing the efficiency of managerial solutions.

Learn more about smart manufacturing using IoT.

Virtual Reality

Virtual reality is a type of world presentation delivered to people via their feelings. The transmission can be carried out using various technical means, such as helmets, glasses, and retinal monitors. While aiming at triggers, these devices open for users interactive content that can be managed in real-time and space.

BigData

Every day a great deal of information, which is difficult to analyze using usual software, appears in the world. Scientists create new methods and tools capable of processing terabytes of data. All information is gathered in special places, data centers, where it is promptly analyzed.

3D printing

Traditional printers are improved all the time and now allow users not only to print documents in hard copy but also perform 3D printing, i.e. create objects based on three-dimensional drawings. Additive manufacturing stimulates the development of Industry 4.0 manufacturing and allows companies to produce more personalized goods.

Cybersecurity

The Fourth Industrial Revolution has led to the emergence of the notion of “cybersecurity”. The implementation of digitization contributes to the arrival of the Internet a new generation of criminals who can easily get access to people’s personal information. Cybersecurity provides for a set of methods aimed at protecting computer networks from various threats, and one essential tool in this endeavor is the use of a Virtual Private Network (VPN). A VPN enhances cybersecurity by encrypting internet connections, safeguarding sensitive data, and providing a secure pathway for communication over the digital landscape.

Cloud Computing

Cloud computing is understood as providing users with servers, software, databases, intellectual analysis over the Internet. All programs can be launched and display their results in the windows of usual browsers on the computer but the applications and information necessary for work are stored on remote servers. The computer equipment, performing cloud calculations, is called “cloud’. The technology increases resource flexibility, speeds up the implementation of innovations, and has high scalability, which ensures cost savings for users.

Navigine Solutions in Industry 4.0

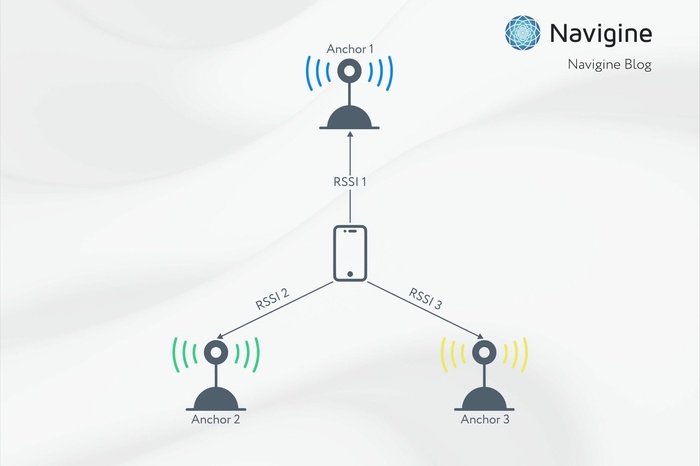

Navigine keeps up with the time and develops innovative tools that can be confidently called the elements of Industry 4.0, including such software products as Navigine SDK and Navigine Tracking which are used for realizing indoor navigation and positioning, tracking assets.

Clients are provided with the geopositioning platform that allows companies to develop location-based mobile applications and web services. While implementing into the company infrastructure, the system allows tracking objects, sending out push notifications with relevant content, gathering analytics, etc. We offer complex solutions that ensure manufacturing digitization and effective business process optimization.

The system helps:

- Reduce the number of emergencies.

- Shorten the time of response to emergencies.

- Logistics process optimization.

- Reduce costs on fictitious man-hours and costs on transport downtime.

In the modern world, when the competition between companies is very high, it is important to implement various advanced technologies. The software solutions from Navigine allow you to improve the performance of your company.