-

Products

- Solutions: Navigine Platform

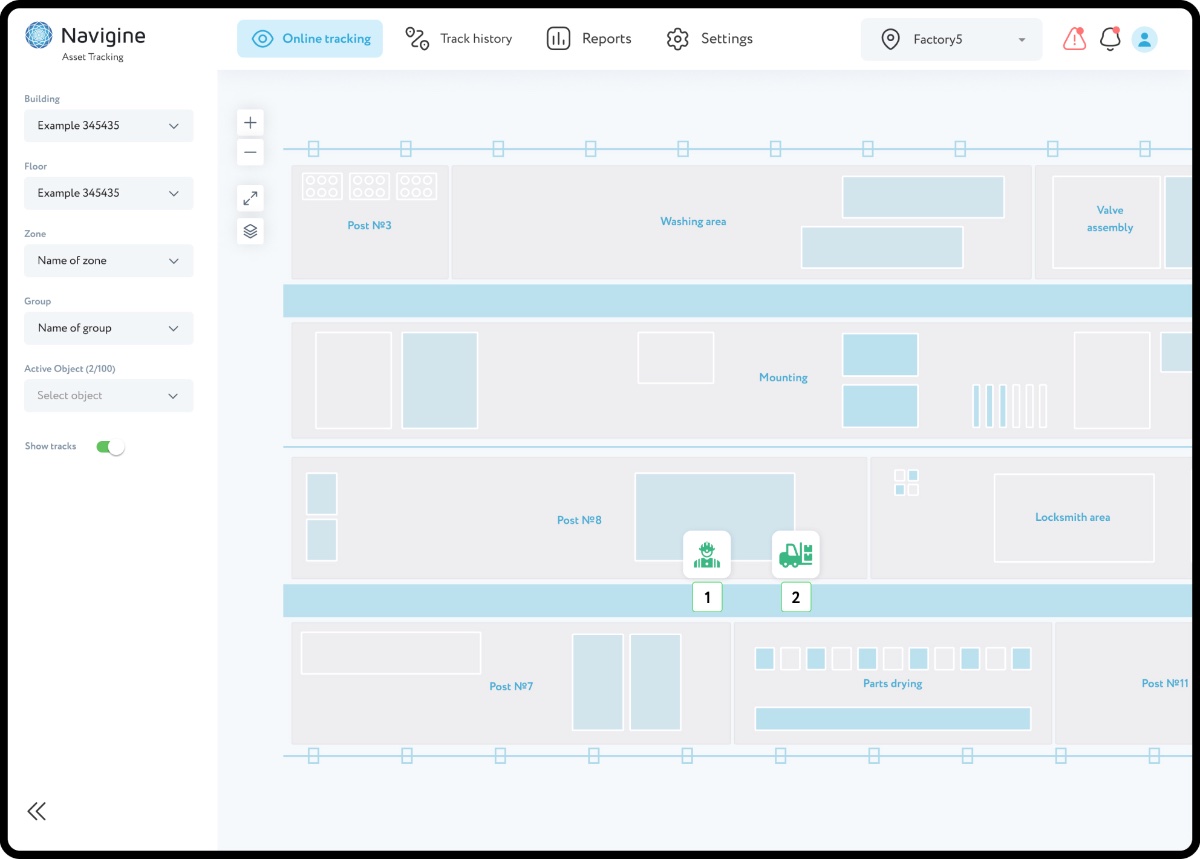

- Navigine Tracking platform

- Navigine SDK

- Demo Kit

- Features: Indoor Wayfinding

- Geofencing

- Examples: Use cases

- Pricing

- Tracking Accuracy Demo

- RTLS Platform Demo

- Industries

-

Technology

- Hardware: UWB

- Wi-Fi Positioning

- BLE Positioning

- Wi-Fi RTT

- Ultrasonic

- AoA

- BLE Tracking

- Wi-Fi Tracking

- Wireless Mesh

- Software: Zone-based Localization Algorithm

- Open source

- K-Nearest Neighbours Positioning Algorithm

- Inertial navigation

- Particle Filter

- RSSI Method

- Devices All devices

- Bluetooth® Low Energy Tags

- Bluetooth® Low Energy (IoT) Gateway

- Ultra Wideband Tags

- Ultra Wideband Antennas

- Developers

- About us

- Navigine Store

- EN

(1).svg)

.svg)

(1).svg)

.svg)

.svg)

.svg)