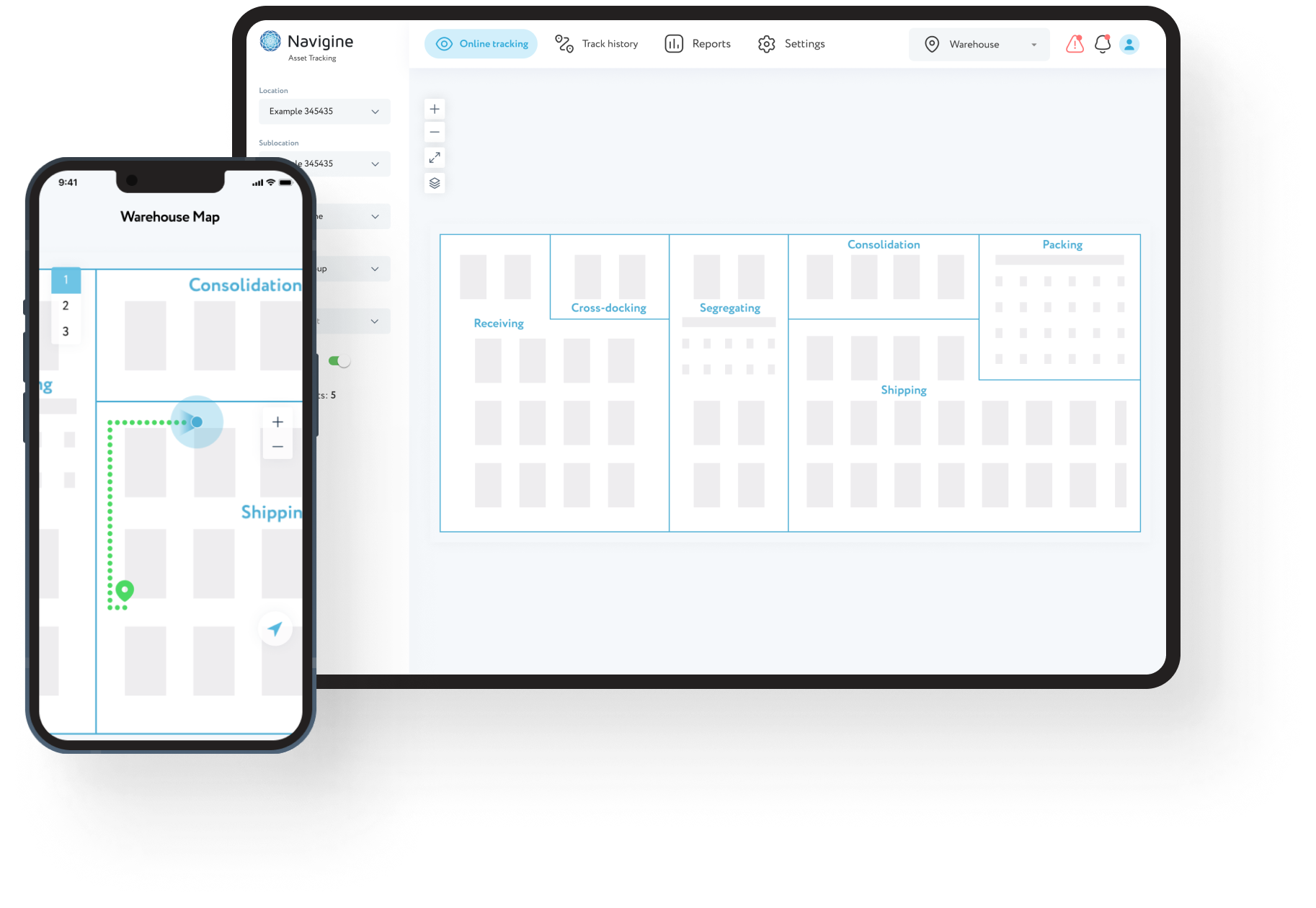

Modern enterprises and industry facilities are constantly looking for new tools to enhance business efficiency and manufacturing processes which in the end results in reduced costs. Nowadays all manufacturers, operating in the time of the 4th industrial revolution, need to accumulate more and more real-time data to identify and evaluate the output of each particular employee, to set up the most appropriate workload, to decrease production costs per unit, and to reduce the number of work accidents. And so-called RTLS in manufacturing, like indoor navigation, is one of the most promising technologies for this.

Navigine offers a range of advanced solutions tailored for industrial environments. Navigine products serve the purpose of improving industrial workplace safety and increasing labor efficiency.

Navigine leverage AI-driven technologies and tools to deliver the best solutions for manufacturing and other industries.

Ensure work efficiency

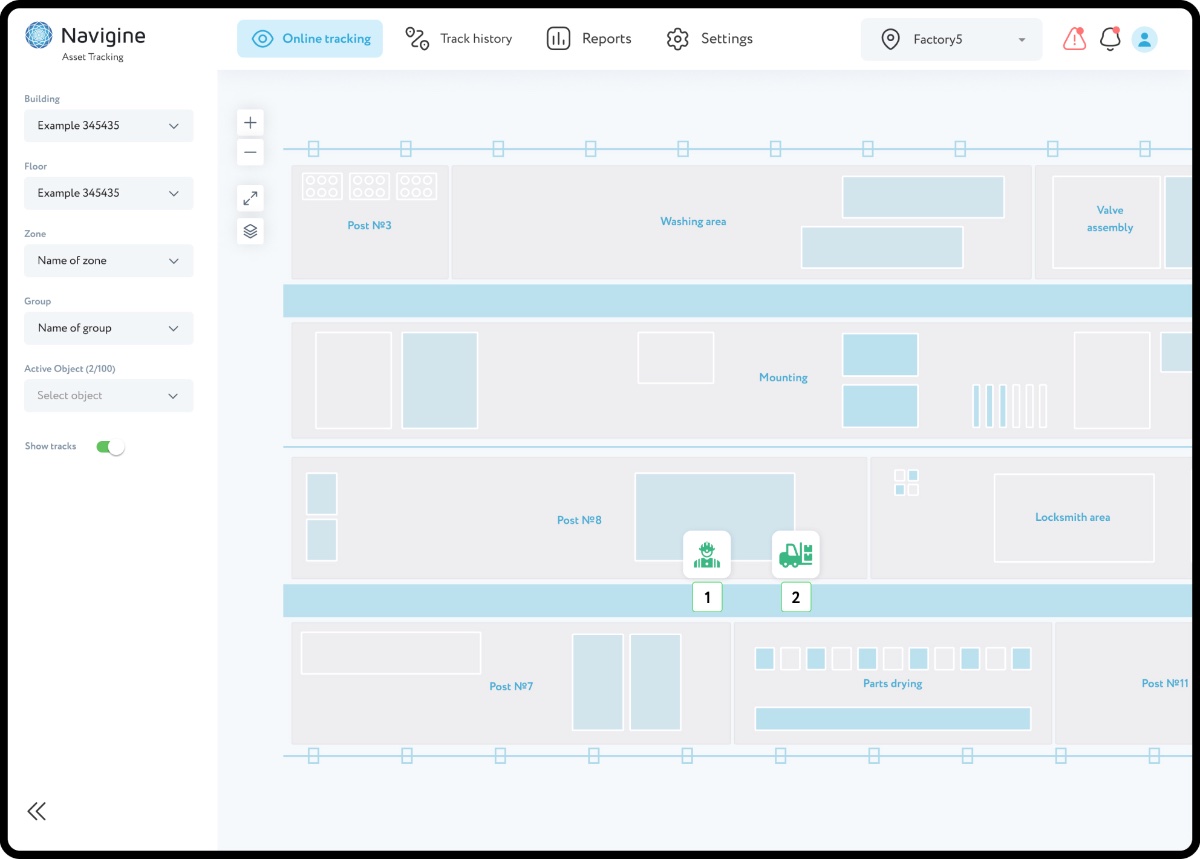

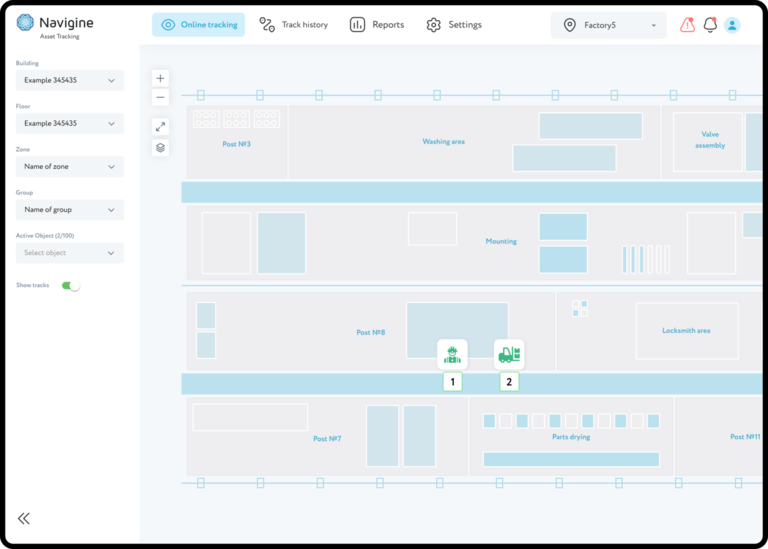

By employing RTLS technologies enterprises can improve working efficiency of employees, digitalizing various processes, creating a new instruments for workflow productivity analytics and getting a full picture of a work-day

Always stay in the loop

Understanding how employees and service personnel fulfill their duties in a factory can help enterprises in optimizing working resources and resolving issues by monitoring staff and outstaff workflow

Get hold of valuables

There are a lot of valuable vehicles and equipment that can be lost or stolen in a factory. With asset tracking, staff can easily monitor location of all valuables and also get relevant information, such as equipment number and purchase date.

Solve safety-related issues

By employing asset tracking technologies, enterprises can create situation awareness, detecting security-related challenges, creating special heat maps of indoor movement. RTLS-powered systems can contribute to mitigating risks to public safety and health